Wednesday, July 25, 2007

steering and brakes

my dad showed up monday evening and was ready to get to work on the welding, so we dived in. first thing was to weld the steering column to the firewall dash support.

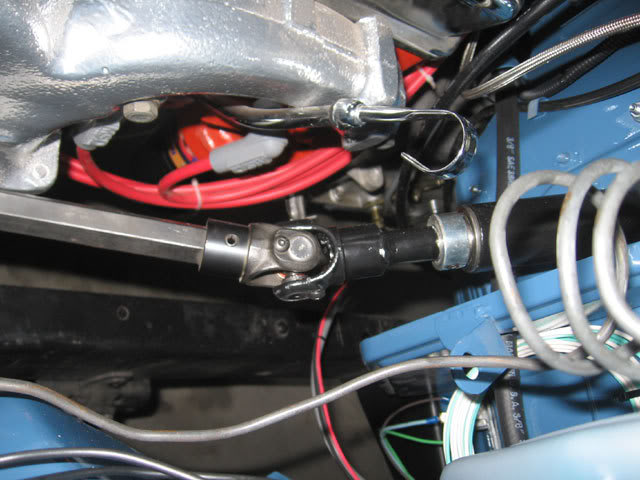

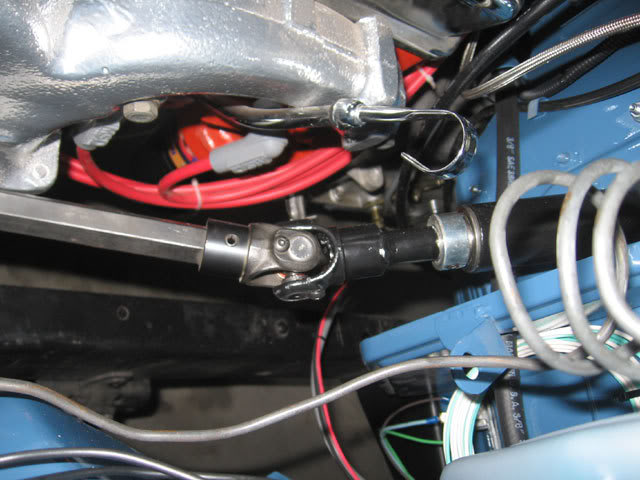

next up was welding the actual steering shaft to the u-joint. this was the critical weld, and i think my dad was impressed with the way it turned out.

we did a few other miscellaneous things, and finally decided to call it a night at midnight. the next morning, i got all of the welded parts primed and painted while my dad started welding the steering box plates to the frame. there was quite a bit to weld, and some upside-down crazy angles, but in the end, it turned out good and most importantly, strong.

once everything was welded up and painted, we installed the brake pedal and then slid the steering column into place. we had to spend a little time getting the steering wheel adjusted just right so that it was not too compressed against the column, but we finally got it perfect.

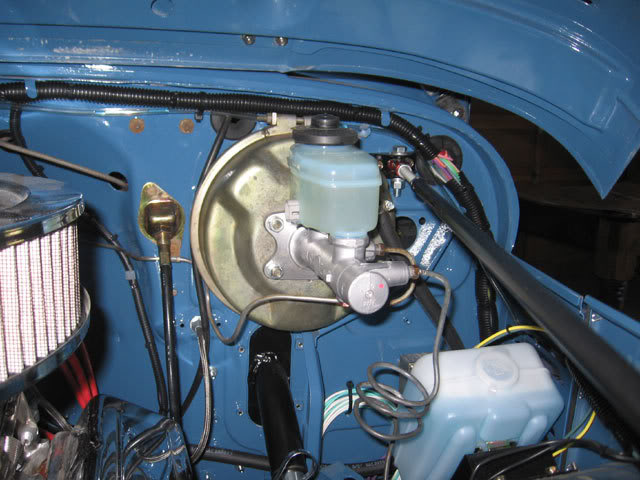

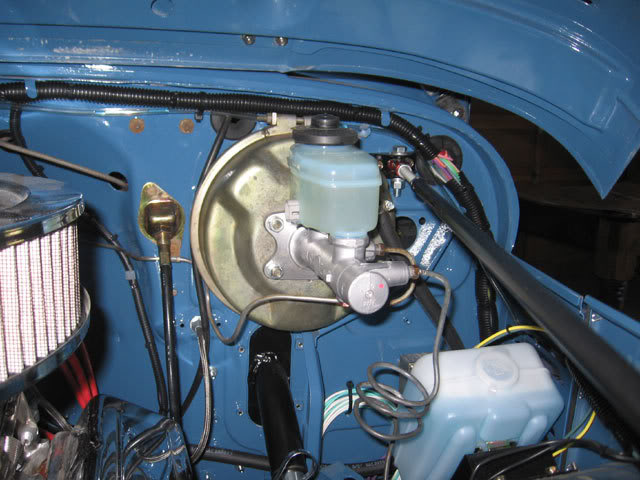

with the steering finished, next up was the brakes. my dad donated his original brake booster that was in much better shape than mine. after some scrubbing with the brillo pad, it looked just like new. we bolted up the new master cylinder (from an fj80 with no ABS) and installed the whole unit. a few days before, i had run the remaining brake lines, so finishing the brakes was as easy as screwing in the two hard lines.

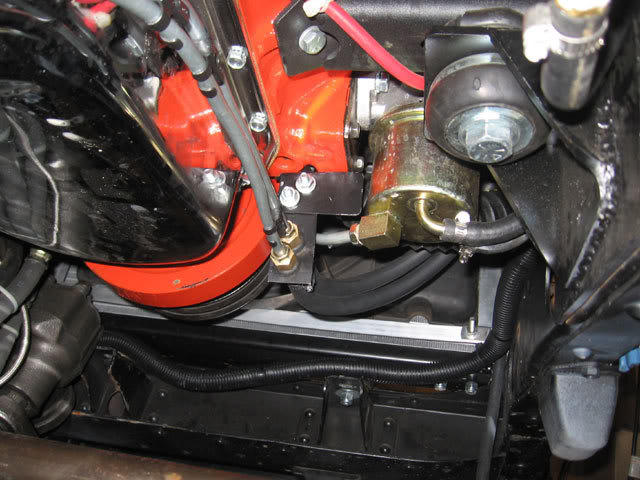

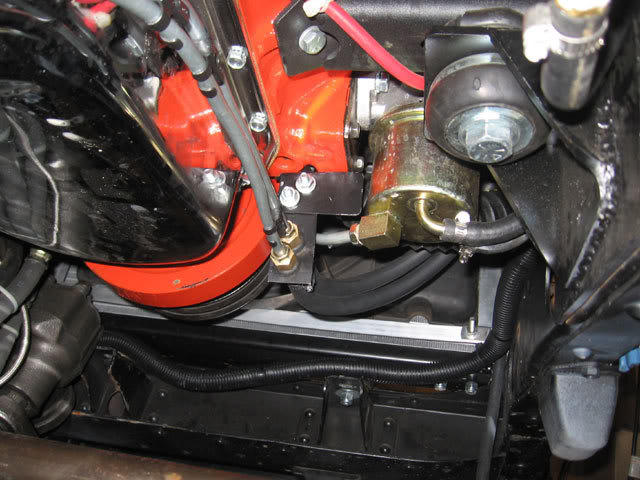

the next thing to complete was the transmission cooler lines. after a quick trip to the parts store for some vacuum hose and transmission cooler hose, we were back at it. the lower bracket that i had made where the hard lines connected to the rubber lines bolted on in a hard-to-get-to spot that took some time to work out, but we finally got it. we put the radiator back in, hooked up the transmission cooler lines and the radiator hoses and crossed that off the list.

the only thing left to do before we could test drive it was to bleed the brakes. with my dad and ryan doing most of the dirty work, we did the front two in a matter of minutes and it was on to the back. try after try, no fluid was making it to the calipers. i suspected that maybe something was clogging the lines, but we finally figured out that no fluid was even coming out of the master cylinder for the back brake circuit. we tried everything, but we couldnt get fluid out of it. we finally took a break to come in and eat some pizza and think things over. after dinner, i did some research on the internet and based on that, decided that we needed to 'bench bleed' the master cylinder. so we drained it, took it off, and used some old brake lines and some windshield washer tubing to make a make-shift bleeder kit. with the first long push of the rod, lots of air and then fluid finally came out of the back brake circuit. we finished bench bleeding the master cylinder and then installed it back into the landcruiser. we re-bled the front brakes just in case, and then did the back. they bled fine this time, but now there was a new problem - the lines were leaking at almost every connection. oops - i had installed those almost two years ago and never did tighten them. we tightened them up, but two connections were still leaking. my dad was headed out early the next morning, but i finally decided that we just needed to call it a night.

the next morning i spent some time thinking abou the issues and how to solve them. that afternoon when i finally had the chance to spend some time working on it again, i decided to take the whole back portion of the brake lines off and re-assess everything. ryan helped me by cleaning up the tee fitting and the hose ends, while i made a new bracket to position the tee in a better spot. we re-connected all of the lines to the tee and double checked that everything looked good before installing the whole unit back under the landcruiser. i pumped up the brakes and there were no leaks. we went ahead and re-bled the front brakes and then did the rear. the finally bled properly and with no leaks. at that point, i had power, steering, and brakes - all of the ingredients required to actually drive the thing for the first time.

next up was welding the actual steering shaft to the u-joint. this was the critical weld, and i think my dad was impressed with the way it turned out.

we did a few other miscellaneous things, and finally decided to call it a night at midnight. the next morning, i got all of the welded parts primed and painted while my dad started welding the steering box plates to the frame. there was quite a bit to weld, and some upside-down crazy angles, but in the end, it turned out good and most importantly, strong.

once everything was welded up and painted, we installed the brake pedal and then slid the steering column into place. we had to spend a little time getting the steering wheel adjusted just right so that it was not too compressed against the column, but we finally got it perfect.

with the steering finished, next up was the brakes. my dad donated his original brake booster that was in much better shape than mine. after some scrubbing with the brillo pad, it looked just like new. we bolted up the new master cylinder (from an fj80 with no ABS) and installed the whole unit. a few days before, i had run the remaining brake lines, so finishing the brakes was as easy as screwing in the two hard lines.

the next thing to complete was the transmission cooler lines. after a quick trip to the parts store for some vacuum hose and transmission cooler hose, we were back at it. the lower bracket that i had made where the hard lines connected to the rubber lines bolted on in a hard-to-get-to spot that took some time to work out, but we finally got it. we put the radiator back in, hooked up the transmission cooler lines and the radiator hoses and crossed that off the list.

the only thing left to do before we could test drive it was to bleed the brakes. with my dad and ryan doing most of the dirty work, we did the front two in a matter of minutes and it was on to the back. try after try, no fluid was making it to the calipers. i suspected that maybe something was clogging the lines, but we finally figured out that no fluid was even coming out of the master cylinder for the back brake circuit. we tried everything, but we couldnt get fluid out of it. we finally took a break to come in and eat some pizza and think things over. after dinner, i did some research on the internet and based on that, decided that we needed to 'bench bleed' the master cylinder. so we drained it, took it off, and used some old brake lines and some windshield washer tubing to make a make-shift bleeder kit. with the first long push of the rod, lots of air and then fluid finally came out of the back brake circuit. we finished bench bleeding the master cylinder and then installed it back into the landcruiser. we re-bled the front brakes just in case, and then did the back. they bled fine this time, but now there was a new problem - the lines were leaking at almost every connection. oops - i had installed those almost two years ago and never did tighten them. we tightened them up, but two connections were still leaking. my dad was headed out early the next morning, but i finally decided that we just needed to call it a night.

the next morning i spent some time thinking abou the issues and how to solve them. that afternoon when i finally had the chance to spend some time working on it again, i decided to take the whole back portion of the brake lines off and re-assess everything. ryan helped me by cleaning up the tee fitting and the hose ends, while i made a new bracket to position the tee in a better spot. we re-connected all of the lines to the tee and double checked that everything looked good before installing the whole unit back under the landcruiser. i pumped up the brakes and there were no leaks. we went ahead and re-bled the front brakes and then did the rear. the finally bled properly and with no leaks. at that point, i had power, steering, and brakes - all of the ingredients required to actually drive the thing for the first time.